The heat preservation effect of industrial kiln furnace is one of crucial factors that affect specific power consumption. Develop a kind of service life to grow and the product that can reduce quality of body of heater is very be necessary. JM-28 belongs to Molaishi light qualitative adiabatic brick, have high temperature capability the characteristic with good, low cost, can use at kiln furnace liner, can reduce body of heater effectively not only quality, managing light, still can prolong lining service life, reduce uphold charge.

JM-28 Mo Laishi pledges adiabatic brick is made gently

With industrial AL2O3 pink, clay, agglomeration good aluminous alumina and partial cyanite are given priority to want raw material, add wood chip (1mm is chosen) beg with polystyrene (diametical 2~0.5mm) preparation pledges gently brick. In joining fine white of industrial AL2O3 pink, aluminous, cyanite, clay mixer first, work mix 3~5min, add polystyrene ball, wood chip and bond next (adscititious) , edge border agitate, after mixing even, go out grind.

Use crowded mud law to shape. After 48h of ℃ of 50~60 of wet base course and 100~110 ℃ 72h are dry after shaping firing. Firing temperature control is in 1400~1500 ℃ , heat preservation 8h. The exterior that checks sample according to relative standard check and manage change target.

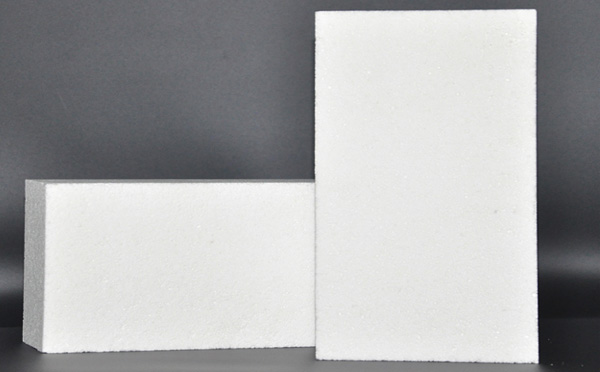

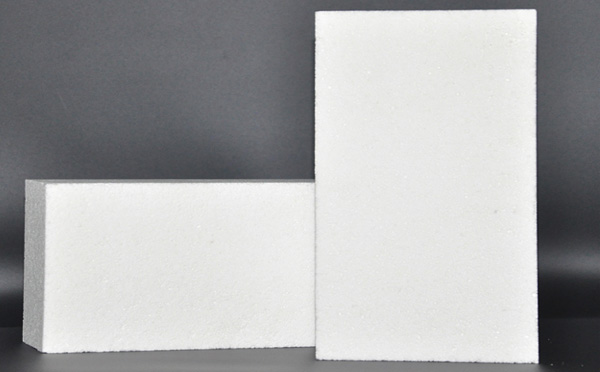

JM-28 Mo Laishi of production pledges gently exterior of adiabatic brick finished product is white, edges and corners trenchant, size is exact. Its manage changes index to be: AL2O3=67.99% , fe2O3 = 0.87% , bulk density is 0.8g·cm, compression intensity is 2.3MPa, change of the line after 1500 ℃ 8h is burned is —0.1% , thermal conductance (800 ℃ ) for 0.24W·m-1·K-1.

Turn index result according to manage knowable: Content of AL2O3 of finished product of light qualitative brick is 67.99% , explain this matchs more than generating Molaishi: Fe2O3 content < 1% , exterior of the adobe after be being burned so is white (if iron content on the high side, the adobe after burning is aglow) . Compression intensity satisfies a standard to ask (≥2.1MPa) , because industrial AL2O3 is in,be firing 13% bulk systole of the left and right sides arose in the process, those who be helpful for compression intensity rise. Clay and industrial AL2O3 are in firing the bulk that different level appeared in the process is contractive, and aluminous Molaishi changes generation bulk to expand, of cyanite decompose reaction to also produce bulk to expand, systematic bulk expands and systole offsets each other make change of product whole line not big, change of the line after 1500 ℃ 8h burns is only - 0.1% : Thermal conductance (800 ℃ ) for 0.248W·m-1·K-1, because the experiment is medium,basically be arose after added wood chip and polystyrene spherule are firing even small 7 aperture, constituent structure is even, thermal conductance is low, achieved energy-saving result.

The application of the product

The liner of job of shuttle type kiln that JM-28 Mo Laishi pledges adiabatic brick applies at ceramics works gently, 1400 ℃ control normal use temperature, high temperature resistant function of function, heat conduction function, accumulation of heat all compares cite data advantageous and service life is long, improved the quality of the product and productivity, improved working environment. Use the air consumption of every kiln after JM28—0.8 Mo Laishi pledges the brick is working line gently to be controlled for 160Kg, mix a structure than former brick every kiln but managing light 40Kg left and right sides, energy-saving advantage is clear.

JM-28 Mo Laishi pledges adiabatic brick has bulk stability gently intensity of good, compression tall, thermal conductance is small waited for an advantage to achieve managing light gas and the goal that reduce kiln style quality.