Current various in aluminous products industry aluminous fusion furnace are gone to ceaselessly large change development,

Fireproof material

Use in frit aluminous furnace mar main the following respects:

What ① craft operates is undeserved, if control of aluminous fluid temperature is undeserved, line of aluminous fluid broken bits did not detect in time.

② lining

Fireproof material

Off quality, used unqualified fireproof material to perhaps introduce the product of low character to save cost.

The technology that ③ lining build by laying bricks or stones builds construction and drying-out is incorrect, use like hearth

Do not stick aluminium pouring makings

Irrigating in building a course, do not have according to irrigate it is good to build craft construction to do a model, expand seam, the craft such as conserve. Additional drying-out is done not have according to warm up graph accomplishs reasonable drying-out arrangement. The health that puts an end to ability of above tripartite surface to assure lining of frit aluminous furnace only moves.

Raised more slashing requirement to fireproof material. The temperature inside frit aluminous furnace is not high, it is 800~950 ℃ commonly, but because aluminium and its aluminium alloy are active tall, the active of the water with 40 ℃ spends melt hind to be close to quite, have extremely strong osmotic, wet fireproof material produces very easy profit to it chemical reaction, cause change of fireproof material bulk, produce crackle and destroy fireproof data stage by stage. So the fusion equipment such as frit aluminous furnace, reverberator crucible furnace uses fireproof material to must want to get ameliorative ability raise fusion life to reduce spend cost.

Although aluminous ingot or useless aluminium are fused although the temperature after has 800~900 ℃ only, but the magnesium in aluminium and its alloy, silicon, manganese very lively, very easy with a few chemistry in fireproof material elemental happening reacts, have very high evaporate steam pressure than waiting like magnesium like a few alloying element, its vapour is easier than aluminous fluid infiltration is fireproof material, and infiltration is oxidized again subsequently after fireproof material, bring about fireproof material finally degenerative, structure is loose with attaint.

So we analysed frit aluminium fireproof material mars furnace to basically have the following 3 reasons.

The active as a result of aluminous water spends ① to be provided urgently osmotic, in the stoma in receiving fireproof data or petty break can be being permeated in use process, create fireproof material structure gradually loose and flake, mar fireproof material finally: And aluminium and its alloy produce physics, chemical reaction extremely easily with the impurity in fireproof material, the material that reaction process makes can make aluminous product quality is affected.

② aluminous fluid and fireproof material react and adhere arrives above fireproof material, form the surface to written guarantee bag of tumour, beat is mixed sedimentary, clear not easily, clear through mechanical method commonly, can cause damage to fireproof material.

③ frit aluminous furnace is producing the feed in raw material in the process, gather up the mechanical operation such as broken bits, wait to furnace case, boiler setting, hearth undertake bumping, wear away very serious, also be a when fireproof material mars frit aluminous furnace main reason.

④ increases the compact density of fireproof material, reduce the porosity of fireproof material. Fireproof material oneself sends density tall, porosity is low, can prevent the osmosis of aluminous fluid and its alloy effectively:

The aggressivity of the water that fight aluminium of ⑤ fireproof material. Fireproof material fights aluminous water wetability admirably, can prevent aluminous waterlogging effectively to appear, prevent aluminous water and adhere of aluminous broken bits. The SiO2 in fireproof material and impurity are extremely easy with aluminous fluid medium AL, Mg happening reacts, cause change of fireproof material bulk at the same time, make fireproof material forms crackle, quicken aluminous water to be eroded to the middle of fireproof material. Accordingly, the aluminous content of fireproof material is higher, pure degree taller, reduced the odds that produces reaction with aluminous water, fight aggressivity to had been jumped over. In the meantime, also can add additive, form covering layer the salt that be like barium, chromic salt with aluminous water reaction, increase fireproof material fight aggressivity: The wearability of ⑥ fireproof material. The wearability of fireproof material basically is to should increase its strength, can increase fireproof material effectively fight wear away, fight mechanical percussive function.

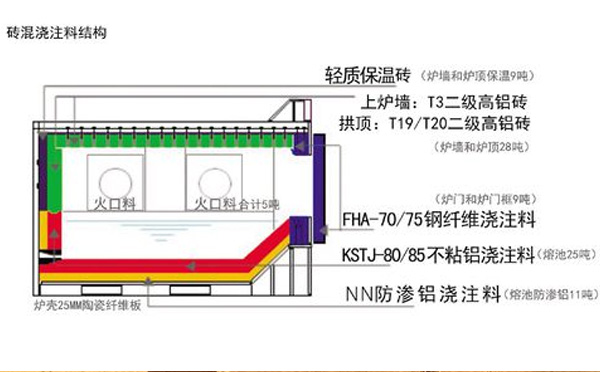

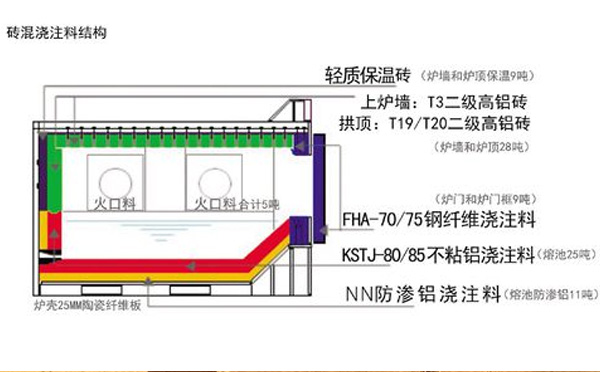

1, the key is the lining life that should improve frit aluminous furnace, want to try to prevent the infiltration of aluminous fluid above all, it is the formation that how makes after infiltration next the vitrification layer of compact layer and tall viscosity, in addition still need those who improve fireproof data to fight wear away and fight thermal shock function. In the light of the analysis of the above lining reason of frit aluminous furnace we developed frit aluminous furnace to be fought with high strenth what aluminium is permeated and fight aluminous fluid adhere is pouring makings.

2, the fluid that fight aluminium is permeated pouring the material of makings chooses character, the chemical character that should reach material from alloy above all considers, use the capable person that does not get alloy and slag to erode to pledge ability makes sure material has good impervious to show performance only: Consider even next pouring of makings fight wear away and fight thermal shock function.

3, the test of aluminous broken bits shows the material after joining is fighting those who permeate function to go up to rise, the osmosis after making sure lining is wet phenomenon, be in again after the growth that the frit aluminium of processing factory of some large aluminium material got test and verify made service life go up on furnace, managing what maintenance cost assured to produce thereby is normal cast with.